Low-Volume Manufacturing: A Comprehensive Guide to Injection Molding

In the context of industrial production, low-volume manufacturing can be a challenging task. However, with the advancement of technologies like injection molding, companies like Huapin are revolutionizing the manufacturing landscape.

The Basics of Injection Molding

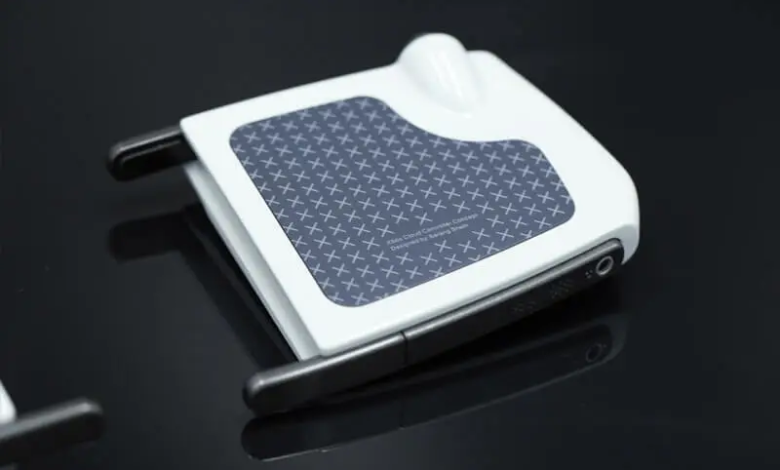

Injection molding is a highly effective manufacturing process where molten material is injected into a mold and cured to create intricate shapes. It is widely used in various industries, including medicine, aerospace, and consumer products. Huapin, a leading brand in the industry, offers injection mold prototyping services that enable customers to test their designs for manufacturability and functionality.

Advantages of Injection Molding for Low-Volume Manufacturing

- Efficiency: Injection molding enables short lead times for large orders, making it an efficient option for low-volume manufacturing.

- High tensile strength: Injection-molded parts can be reinforced with fillers, enhancing their tensile strength for durability.

- Ready-to-go finish: Injection-molded parts come out of the mold with a smooth finish, eliminating the need for further refinement.

Conclusion

Huapin’s expertise in low-volume manufacturing through injection molding makes them the ideal partner for businesses looking to bring their designs to life. With their efficient processes, attention to detail, and wide range of material options, Huapin ensures high-quality products at affordable prices. Whether it’s medical devices, packaging, or automotive components, Huapin’s services are tailored to meet the unique needs of every industry. Embrace the power of low-volume manufacturing with Huapin and take your business to new heights.